Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM) is certainly the technology most familiar to the general public. As one of the cheapest technologies available, it is now widely used by home users and SMEs.

The concept is very simple, involving the extrusion of a heated thermoplastic polymer thread through a nozzle (or printhead). The head follows the path defined by the 3D file to reproduce the part layer by layer.

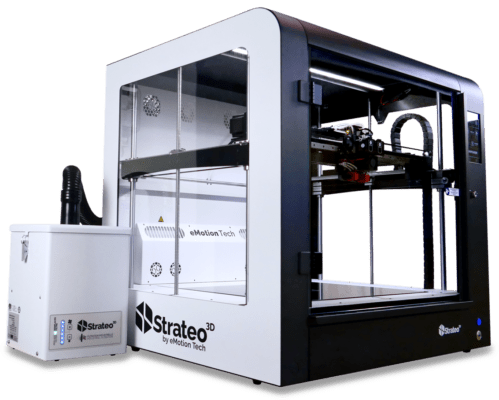

At Axis, we use professional FDM printers whose print quality and repeatability enable us to meet all our customers’ needs.

The printing dimensions of our largest machine enable us to produce parts up to 900 x 600 x 900 mm.

In addition to its attractive price, wire-dispensing technology offers great flexibility in terms of the materials used. From the simplest bio-sourced plastics such as PLA, to more technical materials like ABS, nylon, ASA, polycarbonate or Ultem, not forgetting TPU (flexible plastics) and filled filaments (wood, composite fibers…). The choice of colors is also very wide, allowing an infinite number of combinations.

If you have a specific project in mind, don’t hesitate to

contact

to find the best materials together.

At Axis, which focuses on 3D printing for businesses, we work mainly with materials for professional prototyping. However, if you have a specific requirement, please do not hesitate to contact us so that together we can define the best material for your project. You can also consult our material sheets.

Stock and commonly used materials:

For the dimensions of your parts, we are able to comply with standard NFT 58-000 normal class.

For your 3D printing projects using molten wire technology, please allow 2 to 5 working days, depending on the size and finish chosen. For mini-series, please contact us for a precise lead time based on your parts and quantities.

For the design of your parts, allow for a minimum wall thickness of 0.8 mm.

Several steps are required to produce a part using molten wire technology:

To find out more about our other additive manufacturing production resources, please visit our our machines page.

Need a quote or information on rapid prototyping?

Ask us for a quick quote or call us on +33 (0)5 55 06 17 17